Industrial automation is an intricate world. Get it wrong, and efficiency and confidence will be lost to spamulence. A proximity switch is a necessary sensor without physical contact that senses whether or not an object is present, and it fulfils an important role in automation systems. Given the many different types of switches and unique needs of each application, choosing the right switch is no easy feat. This paper is dedicated to helping you find out how to choose the most appropriate proximity switch for your particular situation.

Understanding Proximity Switch Types

Before you start choosing, it's important to understand the different types of proximity switches that are available.

Inductive Proximity Switches are suitable for detecting metal objects which have been brought near to them in some way; they are sturdy against environmental effects.

Capacitive Proximity Switches, can detect objects made of various substances including non-metals, are useful in sterile environments.

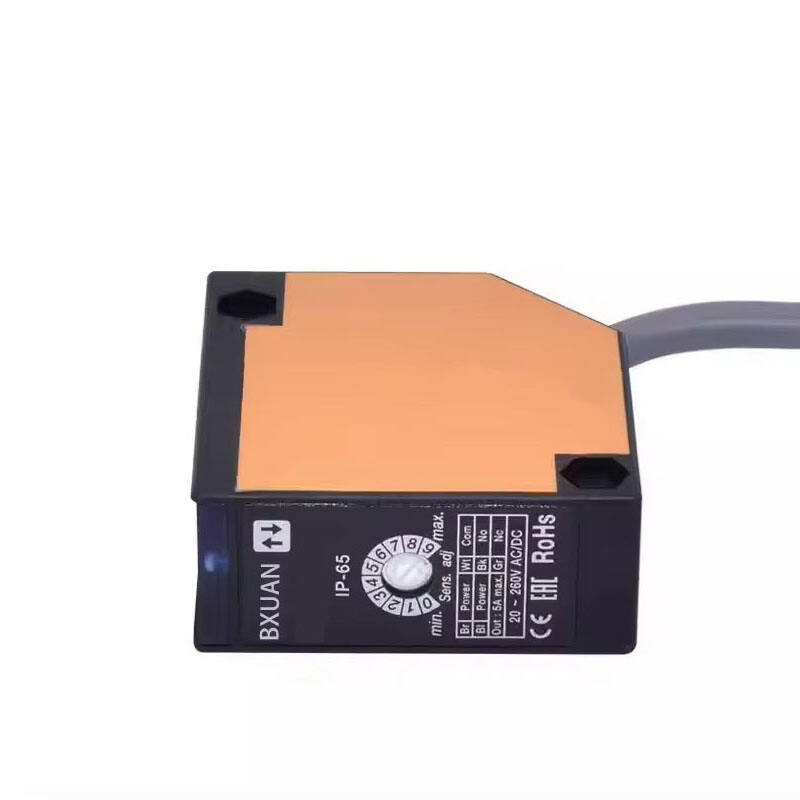

Photoelectric Proximity Switches use light beams to detect objects; they are well suited to high-precision applications

Ultrasonic Proximity Switches are good for detecting objects even through barriers and in places with poor visibility.

Hall Effect Proximity Switches can sense magnetic fields and they are used in position sensing and speed detection.

Key Factors to Think About

There are several things to keep in mind when deciding on a proximity detector.

What is the material you want to detect? This will have an influence on which way you go. Inductive switches work best with metals, while capacitive and photoelectric ones can sense a wider range of material types.

Environmental Conditions: The switch must work effectively under conditions such as high temperatures, with humidity and dust, or water.

Detection Range and Sensitivity: Decide on the distance at which the switch has to pick up objects and how much sensitivity you need for your process.

Mounting and Installation Considerations: This is where things really pay. Leave nothing to chance--either if it's too difficult to install a given product (even more important for something new), or to let yourself become very positive after a few months of experience.

Output Signal Requirements: Check to make sure that the switch's output signal is compatible with the systems of control which already exist.

Cost and Budget Constraints: Balance the initial cost of the switch against its long-term reliability and maintenance costs.

Compatibility with Control Systems

The switch must be integrated perfectly with your existing control systems. This could involve such things as it must conform to certain communication protocols, or that it can interface with programmable logic controllers (PLC's) and other equipment.

Performance and Reliability

Performance and reliability are the top priority for switches. Until you know which industry safety certifications the switch must have, look only at those switches which meet accepted standards. In addition to this kind of information, careful consideration should also be given to durability and longevity since they can affect total cost of ownership dramatically.

Practical Considerations

Ease of installation, maintenance, and the availability of spare parts and support are practical considerations that must be factored in. Often a switch from a well-known manufacturer with good user reviews and sound after-sales support will have been created for practical use.

Making the Selection

First, get together all the requirements and specifications of your application. Next, choose some switch models that meet these standards for your short list. Ask for samples or demonstrations of the switch's performance under real-world conditions. Finally, do a cost-benefit analysis to ensure that the switch offers the best value for your investment.

Case Studies and Examples

It is inspiring to look at case studies and real-world examples. A factory, for example, may use inductive switches in metal detection on a conveyor belt; whereas a packer facility might employ photoelectric switches for high-precision object positioning.

Conclusion

To select the right proximity switch requires careful thought about what sort of switch is needed, the material to be detected, environmental conditions and compatibility with existing systems. A well-considered choice that takes into account performance, reliability, and practical considerations always meets the requirements of your application.