Introduction

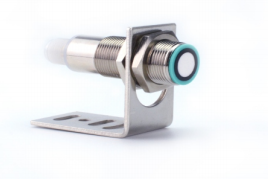

Ultrasonic sensors find their application in a plethora of areas like distance measuring, object detection and level monitoring. These sensors operate by projecting ultrasonic waves and calculating the time it takes for the waves to go back after colliding with any object. But for ultrasonic sensors to measure distance precisely, calibration is required. In this article we will go over how to calibrate an ultrasonic sensor to obtain accurate distance readings.

Ultrasonic sensors are working

How They Work: Ultrasonic sensors work by transmitting sound waves at a frequency higher than the human ear. When these pulses meet an object, the echoes of micro-pulses return to the environment and then back to the receptor area. This time taken by the waves to return back is calculated which helps in deciding the distance of an object from another. The sensor is predisposed to error by environmental variables like temperature, humidity, and surface reflection.

Preparing for Calibration

Tools and Equipment required for Calibration Process Materials required: The ultrasonic sensor, a reference measuring tape/ruler for the distances, a multimeter(if necessary), and calibration software(if needed) Find an appropriate place where the driver is able to be calibrated, and the less driving noise and disturbances would be in this better.

Calibration Process

Here are the steps for calibration:

Setup & Pairing : Setup the ultrasonic sensor to your system as per manufacturer instruction. Make sure it not loose & properly fix in the right direction.

Measuring the known distance Put a reference object at a known range from your sensor. So we want to use this distance and compare it to what the sensor is actually reading.

Record the sensor output Power up the sensor and log the distance measured. The output itself can then be adjusted according to the sensor's calibration settings.

Calibrating: If the sensor does not give you any reading close to the known distance, you may want to adjust calibration settings as well. The exact parameters will differ based on the sensor model, examples might be adjusting gain-offset or other factors.

Checking the Calibration is Correct: Remeasuring between beaker placement according to beaker settings and confirmed from those read back from distance sensor output. It is done by repeating these steps at multiple distances for the sensor to check how accurate its in actual working range.

Common Calibration Techniques

Calibration of Ultrasonic Sensors: Their are two types of calibration practices used for ultrasonic sensors — V-Resonator (also known as fixture) and FR Resonator.

Manual Calibration: The user currently has to set the properties manually from a known reference object at a known distance. While they are a bit finicky and imprecise they still may work for more simple applications.

Automated Calibration: in complex it would be difficult to calibrate every sensor by hand so automated methods are necessary. The software can then adjust the sensor's sensitivity levels according to the feedback from the readings in order to maintain calibration and accuracy.

Calibration Troubleshooting

If you encounter problems such as readings that are inconsistent or significantly different from known distance when calibrating. Issues with either sensor are resolved by verifying the alignment, position, and environmental conditions of that sensor. Make sure the sensor is unobstructed and clean as any blockage will decrease its performance.

Maintaining Calibration

Once your ultrasonic sensor has been calibrated, it is critical to ensure its accuracy. This will allow regular inspections to be made in case something has changed with the sensor due to possible environmental conditions such as changes of pressures, temperature and a calibration process in order to keep it returning data at its best performance. Changing of environmental condition or movement of sensor may require calibration.

Conclusion

Another important step in this regard is to calibrate an ultrasonic sensor before taking distance measurements. In this case, I suggest to keep a sensor working properly over the long time if you adjust its settings following an accurate systematic approach. No matter whether you are handling a small project or an industrial application, calibration of your ultrasonic sensor is crucial which on further implementation shall render reliable and accurate data to work with.