að velja réttanálægðarsnúturbyrjar á því að skilja lykilskilgreiningar þess. Þessar skilgreiningar hafa beinan áhrif á hvernig rofinn virkar í þínu.umsóknVel valinn nálægðarrófinn tryggir nákvæma skynjun, samhæfni við kerfið þitt og kostnaðarsama rekstur. Nálægðarrófinn þjónar fjölbreyttum tilgangi, allt frá iðnaðar sjálfvirkni til neytendatækni. Geta þeirra til að skynja hluti án líkamlegs snertingar gerir þá ómissandi í umhverfi þar sem áreiðanleiki og nákvæmni eru mikilvæg. Með því að einbeita sér að nauðsynlegum skilgreiningum geturðu tekið upplýstar ákvarðanir sem bæta bæði virkni og endingartíma.

gerðir nálægðarbreytinga

Þegar þú velur nálægðarrófinn er mikilvægt að skilja mismunandi gerðir sem eru í boði. Hver gerð starfar á einstökum meginreglum og hentar ákveðnum forritum. Hér að neðan finnur þú yfirlit yfir algengustu gerðir nálægðarrófanna.

innleiðingar nálægðarlykil

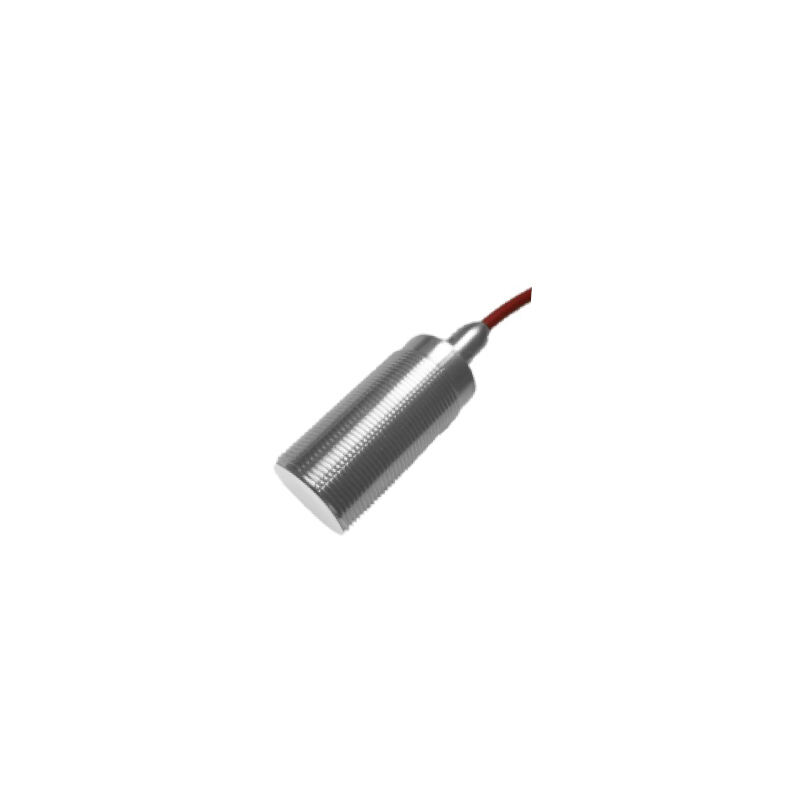

Inductive proximity switches nema málmhluti án líkamlegs snertingar. Þeir virka með því að mynda rafsegulsvið og skynja breytingar sem orsakast af tilvist málms. Þessir rofar skara fram úr í iðnaðarumhverfi þar sem nauðsynlegt er að nema járn- og ójárnmetall.

Helstu einkenni:

Hár endingartími í erfiðum aðstæðum.

Mótstaða gegn óhreinindum, olíu og öðrum mengunarefnum.

Fullkomin fyrir notkun eins og samsetningarlínur, vélmenni og vélarverkfæri.

Ef forritun þín felur í sér málmnám, veita inductive proximity switches áreiðanlega og nákvæma frammistöðu.

Hæfðarhjartahlutar

Capacitive proximity switches nema bæði málm- og ómálmhluti. Þeir starfa með því að skynja breytingar á hleðslu þegar hlutur fer inn í skynjunarsvið þeirra. Þessir rofar eru fjölhæfir og geta numið efni eins og plast, við, gler og vökva.

Helstu einkenni:

Færni til að nema breitt úrval efna.

Hægt er að stilla næmni fyrir sérstakar forritanir.

Algeng notkun í umbúðum, efnismeðferð og hæðarnámi.

Þú ættir að íhuga kapacitive rofa ef forritið þitt krefst þess að greina ekki-málm hlutir eða að fylgjast með vökvastigum.

Magnetsnútar

Segulnálægðarskiptar treysta á segulsvið til að greina hluti. Þeir krefjast seguls til að kveikja á skynjara, sem gerir þá mjög sérhæfða og áreiðanlega. Þessir rofar eru oft notaðir í öryggisviðkvæmum forritum.

Helstu einkenni:

Mikill mótstaða gegn umhverfisþáttum eins og ryki og raka.

Langar skynjunarfjarlægðir miðað við aðra gerðir.

Algengt að nota í dyrastöðu skynjun, flutningakerfum og öryggiskerfum.

Ef nákvæmni og umhverfisþol eru forgangsatriði, þá bjóða segulnálægðarskiptar framúrskarandi lausn.

Með því að skilja þessar gerðir geturðu parað réttan nálægðarskipt við þarfir forritsins þíns. Hver gerð hefur einstaka kosti, sem tryggir hámarks frammistöðu í ýmsum aðstæðum.

með þéttni

Ultrasonic nálgunarskiptar nota hljóðbylgjur til að greina hluti. Þessir skynjarar senda frá sér hárfrekvenst hljóðbylgjur og mæla tímann sem það tekur fyrir bylgjurnar að endurkastast eftir að þær lenda á hlut. Þessi tækni gerir þá mjög áhrifaríka við að greina hluti óháð efni, lit eða gegnsæi.

Helstu einkenni:

Fjölbreyttar greiningarmöguleikar: Ultrasonic skynjarar geta greint breitt úrval efna, þar á meðal málm, plast, gler og vökva. Þeir eru ekki háðir lit eða yfirborðsstrúktúri hlutarins.

Langt skynjunarsvið: Þessir skiptar bjóða upp á lengri skynjunarsvæði miðað við aðra gerð nálgunarskiptar. Þetta gerir þá fullkomna fyrir notkun þar sem krafist er greiningar yfir stærri svæðum.

Hár nákvæmni: Ultrasonic skynjarar veita nákvæmar mælingar, sem gerir þá hentuga fyrir verkefni eins og að fylgjast með hæð, mæla fjarlægð og staðsetningu hluta.

Mótstaða gegn umhverfisþáttum: Þessir skynjarar virka vel í krefjandi umhverfi. Drit, óhreinindi og raka hafa lítil áhrif á virkni þeirra.

Algengar notkunir:

Stigamæling: Ultrasonic nálgunarskiptar eru víða notaðir í tankum og silóum til að fylgjast nákvæmlega með vökvastigum eða föstum efnum.

Hlutaskynjun í sjálfvirkni: Þeir eru oft notaðir í flutningakerfum til að skynja hluti óháð efni eða lit.

Bílastæðisaðstoðarkerfi: Í bílaumsóknum hjálpa ultrasonic skynjarar að skynja hindranir og aðstoða við bílastæði.

Vélmenni: Þessir skynjarar gera vélmennum kleift að sigla og forðast hindranir á áhrifaríkan hátt.

Þegar þú þarft nálgunarskiptara sem virkar í fjölbreyttum efnum og umhverfi, skera ultrasonic skynjarar sig úr sem áreiðanlegur kostur. Geta þeirra til að veita stöðuga frammistöðu í krefjandi aðstæðum gerir þá að dýrmætum viðbót við mörg iðnaðar- og viðskiptaleg forrit.

Krafir um notkun

Þegar valið er um nálægðarskiptitæki er mikilvægt að skilja kröfur þínar um notkun. Þessir þættir ákvarða hversu vel skiptitækið mun virka í þínu sérstaka umhverfi og tryggja að það uppfylli rekstrarkröfur þínar.

skynjunarsvæði

Skynjunarfjarlægð hefur mikilvægu hlutverki að gegna við val á réttu nálægðarskiptitæki. Hún skilgreinir hversu langt skynjarinn getur greint hlut. Þú þarft að meta nauðsynlegan greiningarfjarlægð fyrir þína notkun. Til dæmis, ef þú vinnur í iðnaðarumhverfi með stórum vélum, gæti verið nauðsynlegt að hafa lengri skynjunarfjarlægð til að tryggja nákvæma greiningu. Á hinn bóginn gætu forrit eins og smáum sjálfvirkni krafist styttri skynjunarfjarlægða fyrir nákvæma virkni.

Framleiðendur tilgreina oft skynjunarfjarlægðina við fullkomnar aðstæður. Hins vegar geta raunverulegir þættir eins og efni, stærð og umhverfisaðstæður haft áhrif á frammistöðu. Prófaðu alltaf skynjarann í þínu raunverulega uppsetningu til að staðfesta að hann uppfylli þínar þarfir.

umhverfisskilyrði

Umhverfisaðstæður hafa veruleg áhrif á frammistöðu og endingartíma nálgunarskiptis. Þú ættir að meta þætti eins og hitastig, rakastig, ryð og útsetningu fyrir efnum. Til dæmis, ef forritið þitt starfar við öfgahita, veldu skiptis sem hannað er til að þola þessar aðstæður. Á sama hátt, í umhverfi með miklu raka eða efnaútsetningu, veldu skynjara með verndandi húðum eða sterku húsnæði.

Rafsegultruflanir (EMI) eru önnur atriði sem þarf að íhuga. Í aðstöðu með miklu rafmagns búnaði getur EMI truflað virkni skynjara. Að velja nálgunarskiptis með EMI mótstöðu tryggir áreiðanlega virkni í slíkum umhverfum.

Festing og uppsetning

Rétt uppsetning og installation eru nauðsynleg fyrir hámarks frammistöðu skynjara. Þú þarft að íhuga til staðar rýmið og uppsetningarvalkostina sem framleiðandinn býður. Sum nálægðarskiptar bjóða upp á flöt uppsetningu, sem gerir þeim kleift að sitja í jafnvægi við yfirborðið, á meðan aðrir krafast óflatar uppsetningar fyrir betri skynjun.

Snúrurouting og tengingaraðferðir hafa einnig áhrif á uppsetningu. Gakktu úr skugga um að tengingartýpa nálægðarskiptisins passi við uppsetningu kerfisins þíns. Til dæmis, ef þú kýst fljótar skiptin, gæti tengiltengdur skiptir verið hentugri en einn með föstum snúrum.

Auk þess, hugsaðu um samræmingu skynjarans við markvörpuna. Ósamræmi getur leitt til ónákvæmrar skynjunar eða minnkaðrar skilvirkni. Fylgdu leiðbeiningum framleiðandans um uppsetningu til að ná bestu niðurstöðum.

Gagnrýni

Þegar metið er nálægðarskiptar, gegna frammistöðuspecification mikilvægu hlutverki við að ákvarða hæfi þeirra fyrir þína umsókn. Þessar forskriftir tryggja að skynjarinn virki nákvæmlega og áreiðanlega við mismunandi aðstæður.

Nákvæmni og Endurtekning

Nákvæmni skilgreinir hversu nákvæmlega nálægðarskiptir greinir hlut innan skynjunarsviðs síns. Mjög nákvæmur skiptir minnkar villur, sem tryggir stöðuga frammistöðu. Endurtekning, hins vegar, vísar til getu skynjarans til að greina sama hlutinn á sama fjarlægð endurtekið við eins aðstæður. Þessir þættir eru saman mikilvægar fyrir umsóknir sem krafist nákvæmra mælinga, svo sem vélmenni eða sjálfvirkar samsetningarlínur.

Til að meta nákvæmni og endurtekningu ættirðu að prófa skynjarann í þínu sérstöku umhverfi. Þættir eins og markefni, stærð og umhverfisaðstæður geta haft áhrif á frammistöðu. Að velja nálægðarswitch með háum nákvæmni og endurtekningu tryggir áreiðanlega starfsemi og minnkar hættu á villum í kerfinu þínu.

Viðbragðstíma

Svörunartími mælir hversu fljótt nálægðarswitch bregst við tilvist eða fjarveru hlutar. Fljótari svörunartími er nauðsynlegur fyrir háhraða forrit, eins og flutningakerfi eða sjálfvirkar flokkunarvélar. Tafir í greiningu geta leitt til óhagkvæmni eða jafnvel kerfisbilana.

Framleiðendur tilgreina venjulega svörunartíma í millisekúndum. Þú ættir að velja nálægðarswitch með svörunartíma sem passar hraðakröfum forritsins þíns. Að prófa skynjarann í raunverulegum aðstæðum hjálpar til við að staðfesta getu hans til að halda uppi kröfum kerfisins þíns.

Hysteresis

Hysteresis vísar til mismunarins á milli fjarlægðarinnar þar sem nálægðarskiptin greina hlut og fjarlægðarinnar þar sem þau hætta að greina hlutinn. Þessi sérsniðin kemur í veg fyrir að skynjarinn skiptist hratt á milli á og af þegar hlutir eru nálægt greiningarmörkum. Vel hannað hysteresis svið tryggir stöðuga virkni og minnkar slit á skynjaranum.

Fyrir forrit sem krafist er nákvæmrar stjórnunar, eins og stöðugreiningu eða stigamælingu, ættir þú að velja nálægðarskiptin með lágmarks hysteresis. Þetta tryggir samfellda greiningu og eykur heildartraust á kerfinu þínu.

Með því að skilja þessar lykilsérsniðnar geturðu valið nálægðarskiptin sem uppfyllir frammistöðukröfur þínar. Að meta nákvæmni, svörunartíma og hysteresis tryggir að skynjarinn virkar á áhrifaríkan hátt í forritinu þínu, sem veitir langtíma traust og skilvirkni.

Úttakategundir og samhæfi

Þegar valið er um nálægðarskiptitæki, tryggir skilningur á úttakstegundum þess og samhæfi að það samþættist vel við kerfið þitt. Þessi kafli skoðar helstu þætti sem þú þarft að meta fyrir hámarks frammistöðu.

Raðtölur vs. Stafræn úttök

Nálægðarskiptitæki bjóða venjulega annað hvort raðtölur eða stafræn úttök. Hver tegund þjónar mismunandi tilgangi, allt eftir kröfum þínum um notkun.

Raðtölur: Þau veita stöðugan merki sem breytist eftir fjarlægðinni milli skynjara og markmiðsins. Raðtölur eru fullkomnar fyrir forrit sem krafist er nákvæmra mælinga, svo sem að fylgjast með stigum eða fjarlægð. Til dæmis, í kerfi sem fylgist með stigum í tanki, getur raðtölunálægðarskiptitæki mælt nákvæmlega vökvastigið og sent hlutfallslegt merki til stjórnkerfisins.

Dígitale úttak: Þau senda út tvíundarsignal, annað hvort Á eða AF, byggt á því hvort markmiðið er innan skynjunarsviðs. Dígitale úttak henta vel fyrir forrit þar sem þú þarft aðeins að vita um tilvist eða fjarveru hlutar. Til dæmis, í flutningakerfum getur dígitale nálægðarswitch greint þegar hlutir fara framhjá ákveðnum punkti.

Þú ættir að velja úttakstypuna sem samræmist þörfum kerfisins þíns. Analóg úttak henta forritum sem krafist er nákvæmra gagna, á meðan dígitale úttak skara fram úr í einfaldari skynjunartaskum.

Rafmagns samhæfi

Rafmagns samhæfi tryggir að nálægðarswitchinn virki rétt með núverandi uppsetningu þinni. Þú þarft að íhuga eftirfarandi þætti:

Vinnuspenna: Staðfestu að spennusvið nálægðarswitchins passi við rafmagnsupply kerfisins þíns. Að nota switch með ósamræmda spennu getur leitt til bilunar eða skemmdar.

Úttakaskipulag: Nálægðarskiptar koma oft í PNP (uppsprettu) eða NPN (dýfu) skipulagi. PNP skiptar veita straum til álagsins, á meðan NPN skiptar dýfa straumi frá álaginu. Ákveðið hvaða skipulag kerfið þitt styður áður en þú velur.

Straumstillt: Gakktu úr skugga um að straumstillt skiptisins uppfylli kröfur forritsins þíns. Ósamræmi getur valdið ofhitnun eða bilun.

Prófun á nálægðarskiptinu í kerfinu þínu hjálpar til við að staðfesta rafmagns samhæfi. Þessi skref minnkar hættuna á villum og tryggir áreiðanlega starfsemi.

Tengingarferlar (Kapall vs. Tengill)

Tengingarferillinn hefur áhrif á auðvelda uppsetningu og viðhald. Nálægðarskiptar bjóða venjulega upp á tvær aðal tengingarvalkostir: kapla og tengla.

Kapall tengingar: Þessar rofar koma með fyrirfram tengdum kaplum, sem veita örugga og varanlega tengingu. Kapalltengingar virka vel í umhverfi þar sem skynjarinn er fastur og krafist er sjaldan að skipta um hann. Hins vegar getur verið tímafrekt að skipta um rofa sem tengdur er með kapli ef kapallinn skemmist.

Tengla-tengingar: Þessar rofar eru með aftengjanlegum tenglum, sem leyfa fljótlega og auðvelda skiptingu. Tengla-tengingar eru fullkomnar fyrir forrit sem krafist er að viðhalda oft eða skipta um skynjara. Þeir einfalda einnig uppsetningu með því að útrýma þörf fyrir flókin raflagnir.

Þegar þú velur tengingaraðferð, íhugaðu viðhaldsþarfir forritsins þíns og uppsetningarkröfur. Tengla-tengingar bjóða sveigjanleika, á meðan kapalltengingar veita endingargóða í stöðugum uppsetningum.

Með því að meta úttakstegundir, rafmagns samhæfi og tengingaraðferðir geturðu valið nálægðarskiptara sem samþættist fullkomlega við kerfið þitt. Þetta tryggir skilvirka starfsemi og minnkar líkur á samhæfingarvandamálum.

Þol og efnisval

húsgagnir

Húsnæðisefni nálægðarskiptara gegnir mikilvægu hlutverki í þoli og frammistöðu þess. Þú þarft að velja efni sem passar kröfum umhverfisins sem þú notar. Framleiðendur nota venjulega efni eins og ryðfríu stáli, plasti eða nikkelhúðaðan messingu fyrir skynjara hús. Hvert efni býður upp á einstaka kosti.

Ryðfrítt Stál: Þetta efni veitir framúrskarandi mótstöðu gegn tæringu og slit. Það virkar vel í erfiðum umhverfum, svo sem þeim sem eru í snertingu við efni eða raka. Húsnæði úr ryðfríu stáli er tilvalið fyrir atvinnugreinar eins og matvælavinnslu eða sjóferðir.

Plast: Plastkáp eru létt og kostnaðarsöm. Þau þola tæringu en kunna ekki að standast öfgafullar hitastig eða mikla árekstra. Þessi kápa henta í forrit þar sem þyngdarsamdráttur er nauðsynlegur, svo sem í flytjanlegum tækjum eða léttum vélum.

Nikkel-fóðraður messings: Þetta efni sameinar styrk og tæringarþol. Það býður upp á jafnvægi milli endingar og hagkvæmni. Nikkel-fóðruð messingskáp eru algeng í iðnaðar sjálfvirkni og almennum forritum.

Þegar valið er um efni fyrir kápu, íhugaðu þætti eins og útsetningu fyrir efnum, hitastigsbreytingum og vélrænum álagi. Endingargóð káp tryggir að nálægðarskiptin virki áreiðanlega og endist lengur í krafthörðum aðstæðum.

Áfall og titringsþol

Nálægðarskiptar virka oft í umhverfi með stöðugri hreyfingu eða þungum vélum. Áfall og titringur verða mikilvæg í slíkum aðstæðum. Þú þarft að tryggja að skynjarinn geti staðist þessar krafta án þess að missa nákvæmni eða virkni.

Áfallsvörn: Nálægðarskiptar með háa áfallsvörn geta þolað skyndileg áföll eða fall. Þessi eiginleiki er nauðsynlegur í iðnaði eins og framleiðslu eða byggingu, þar sem búnaður getur lent í óhappum.

Titringsvörn: Stöðugir titringar geta truflað frammistöðu skynjara með tímanum. Skynjarar hannaðir með titringsvörnum halda stöðugleika og nákvæmni í dýnamískum umhverfum. Umsóknir eins og bíla-kerfi eða flutningabelti njóta góðs af þessari eiginleika.

Til að meta mótstöðu nálægðarskiptis, athugaðu tæknilegar forskriftir framleiðandans fyrir áfall og titring. Að prófa skynjarann í raunverulegu uppsetningu þinni hjálpar til við að staðfesta getu hans til að takast á við raunverulegar aðstæður. Að velja rofa með sterka mótstöðu tryggir stöðuga frammistöðu og minnkar hættuna á fyrir tímabundna bilun.

Með því að einbeita sér að efni hússins og mótstöðu gegn áfalli og titringi geturðu valið nálægðarskiptis sem uppfyllir varanleika kröfur forritsins þíns. Þessar íhugun bæta áreiðanleika skynjarans og lengja rekstrarlíftíma hans.

Kostnaður og fjárhagslegar takmarkanir

Þegar þú kaupir nálægðarskiptis er mikilvægt að skilja kostnað og fjárhagslegar takmarkanir. Þessar íhugun hjálpa þér að taka ákvörðun sem jafnar út hagkvæmni og virkni. Með því að meta bæði framfærslukostnað og langtíma kostnað geturðu tryggt að rofinn uppfylli þarfir þínar án þess að fara yfir fjárhagsleg mörk þín.

Jafnvægi kostnaðar og frammistöðu

Að finna rétta jafnvægið milli kostnaðar og frammistöðu er mikilvægt. Ódýrari nálægðarskiptari gæti virðist aðlaðandi, en hann gæti skort þol eða eiginleika sem krafist er fyrir þína notkun. Á hinn bóginn gæti há-endaskiptari með háþróaðri getu farið fram úr raunverulegum þörfum þínum, sem leiðir til óþarfa kostnaðar.

Til að ná þessu jafnvægi skaltu byrja á því að greina lykilspecifikasjónir sem notkun þín krefst. Til dæmis, ef umhverfi þitt krefst þol gegn öfgalegum hitastigum eða efnum, skaltu forgangsraða skiptum með sterku húsnæði. Ef nákvæmni er mikilvæg, einbeittu þér að skynjurum með mikilli nákvæmni og endurtekningu. Með því að samræma eiginleika skiptisins við rekstrarkröfur þínar forðast þú að eyða of miklu í óþarfa virkni.

Þú ættir einnig að íhuga vörumerkið og framleiðandann. Vönduð vörumerki bjóða oft áreiðanlegavörurmeð stöðugum frammistöðu. Þó að þessir rofar geti kostað meira í upphafi, getur gæðin dregið úr hættunni á bilunum og niður í tíma, sem sparar peninga til lengri tíma litið. Berðu saman valkosti frá mismunandi framleiðendum til að finna vöru sem býður upp á bestu gildi fyrir fjárfestingu þína.

Viðhald og skiptikostnaður

Viðhald og skiptikostnaður spila mikilvægt hlutverk í heildarkostnaði eignarhalds. Nálægðarrofi með lægra upphafsverði gæti krafist tíðra viðgerða eða skiptis, sem eykur langtíma kostnað. Á hinn bóginn, varanlegur og vel hannaður rofi gæti haft hærra upphafsverð en lægri viðhaldsþarfir.

Metið væntanlega líftíma nálægðarskiptis. Framleiðendur veita oft upplýsingar um endingartíma skynjarans við ákveðnar aðstæður. Veldu skiptis sem hannað er til að þola umhverfi forritsins þíns til að lágmarka slit og skemmdir. Til dæmis, ef uppsetningin þín felur í sér stöðugar titringar, veldu skynjara með mikilli titringsmótstöðu til að draga úr líkum á skemmdum.

Íhugaðu hve auðvelt er að skipta um skiptis. Gerðir með tengi tengingum einfalda skipti, sem sparar tíma og vinnukostnað. Auk þess, athugaðu framboð á varahlutum. Líkan sem er víða aðgengilegt tryggir að þú getir fljótt fundið varahluti, sem lágmarkar óvirkni.

Regluleg viðhald hefur einnig áhrif á kostnað. Sum nálægðarskiptin krafist reglulegrar kalibrunar eða hreinsunar til að viðhalda nákvæmni. Taktu þessar verkefni með í fjárhagsáætlunina þína. Að fjárfesta í skiptis með lágmarks viðhaldsþörf getur sparað þér tíma og auðlindir yfir líftíma þess.

Með því að meta bæði frammistöðu og viðhaldsþætti vandlega geturðu valið nálægðarswitch sem passar við fjárhagsáætlun þína á meðan það veitir áreiðanlega og skilvirka rekstur.

Sérstakar eiginleikar eða sérsniðnar valkostir

Forritanlegir nálægðarswitchar

Forritanlegir nálægðarswitchar bjóða upp á sveigjanleika og aðlögun fyrir ýmsar umsóknir. Þessir switchar leyfa þér að breyta stillingum þeirra til að uppfylla sérstakar rekstrarþarfir. Þú getur stillt breytur eins og skynjunarvegalengd, svörunartíma eða úttakstegund án þess að skipta um skynjara. Þessi eiginleiki gerir forritanlega switcha að fullkomnum fyrir dýnamískar umhverfi þar sem kröfur breytast oft.

Kostir forritanlegra nálægðarswitcha:

Fjölhæfni: Þú getur notað einn skynjara fyrir marga verk með því að forritaða hann eftir þörfum.

Kostnaðarávinningur: Að draga úr þörf fyrir marga skynjara lækkar heildarkostnað.

Auðvelt í notkun: Framleiðendur bjóða oft notendavænt hugbúnað eða viðmót fyrir forritun.

Til dæmis, í sjálfvirkri framleiðslulínu, geturðu forritað einn nálægðarskiptivirkja til að greina hluti af mismunandi stærðum eða efnum. Þessi aðlögun eykur skilvirkni og minnkar óvirkni sem stafar af skiptivirkjaskiptum. Ef forritun þín krefst sveigjanleika, veita forritanlegir nálægðarskiptivirkjar raunhæfa lausn.

Samþætting við IoT og snjallar kerfi

Nútíma nálægðarskiptivirkjar styðja í auknum mæli samþættingu við IoT (Internet of Things) og snjallar kerfi. Þessir háþróuðu skynjarar geta átt samskipti við önnur tæki, sem gerir rauntíma gagnaflutning og fjarstýringu möguleg. IoT-heimildar nálægðarskiptivirkjar auka sjálfvirkni og bæta ákvarðanatökuferla.

Aðal eiginleikar IoT-samþættra nálægðarskiptivirkja:

Gagnaöflun: Skynjarar senda frammistöðugögn til miðlægra kerfa til greiningar.

Fjarstýring: Þú getur fylgst með stöðu skynjara og frammistöðu frá hvaða stað sem er með tengdum tækjum.

Spá um viðhald: IoT kerfi greina skynjaragögn til að spá fyrir um möguleg bilun, sem minnkar óvirkni.

Til dæmis, í snjallverksmiðju, geta IoT-heimildar nálægðarskiptar sent viðvaranir þegar þeir greina frávik, eins og óvæntar hreyfingar á hlutum. Þessi hæfni gerir þér kleift að takast á við vandamál strax, sem tryggir að reksturinn gangi snurðulaust. Ef uppsetningin þín felur í sér snjallar kerfi, íhugaðu að nota nálægðarskiptar með IoT samhæfi til að hámarka afköst.

Aðlögun á vettvangi

Aðlögun á vettvangi gerir þér kleift að fínstilltu nálægðarskiptar beint á uppsetningarsvæðinu. Þessi eiginleiki tryggir hámarks frammistöðu með því að leyfa þér að aðlaga skynjarann að raunverulegum aðstæðum. Þú getur stillt stillingar eins og næmni, skynjunarsvið eða úttaksskipulag án sérhæfðra verkfæra eða búnaðar.

Kostir aðlögunarhæfra nálægðarskiptar:

Þægindi: Aðlögun á staðnum sparar tíma og útrýmir þörf fyrir skiptin.

Nákvæmni: Fínstilling tryggir nákvæma skynjun í ákveðnum umhverfum.

Fjölbreytni: Þú getur fljótt aðlagað skynjarann að breytilegum rekstrarþörfum.

Til dæmis, í vöruhúsi gætirðu þurft að stilla næmni nálgunarskiptis til að taka tillit til breytilegra stærða eða efna. Aðlögun á vettvangi gerir þér kleift að gera þessar breytingar strax, sem tryggir stöðuga frammistöðu. Ef forrit þitt krefst tíðra breytinga, bjóða aðlögunarhæfar nálgunarskiptar óviðjafnanlegan þægindi og áreiðanleika.

Með því að kanna þessar sérstöku eiginleika og sérsniðnar valkostir geturðu valið nálgunarskiptar sem samræmast þínum einstöku kröfum. Forritanlegar stillingar, IoT samþætting og aðlögun á vettvangi auka virkni og tryggja að fjárfestingin þín sé framtíðarsönn.

Að meta lykilforskriftir er nauðsynlegt þegar valið er nálægðarskiptari. Það tryggir að skynjarinn samræmist þörfum þínum í notkun og virki áreiðanlega í raunverulegum aðstæðum. Að jafna frammistöðu, endingartíma og kostnaðarskiptum hjálpar þér að ná hámarksárangri án þess að eyða of miklu. Settu alltaf langtíma áreiðanleika og samhæfi í forgang til að forðast tíðar skiptin eða truflanir í rekstri. Með því að taka upplýstar ákvarðanir geturðu aukið skilvirkni og tryggt að nálægðarskiptarinn veiti stöðuga gildi yfir tíma.