level ultrasonic sensor

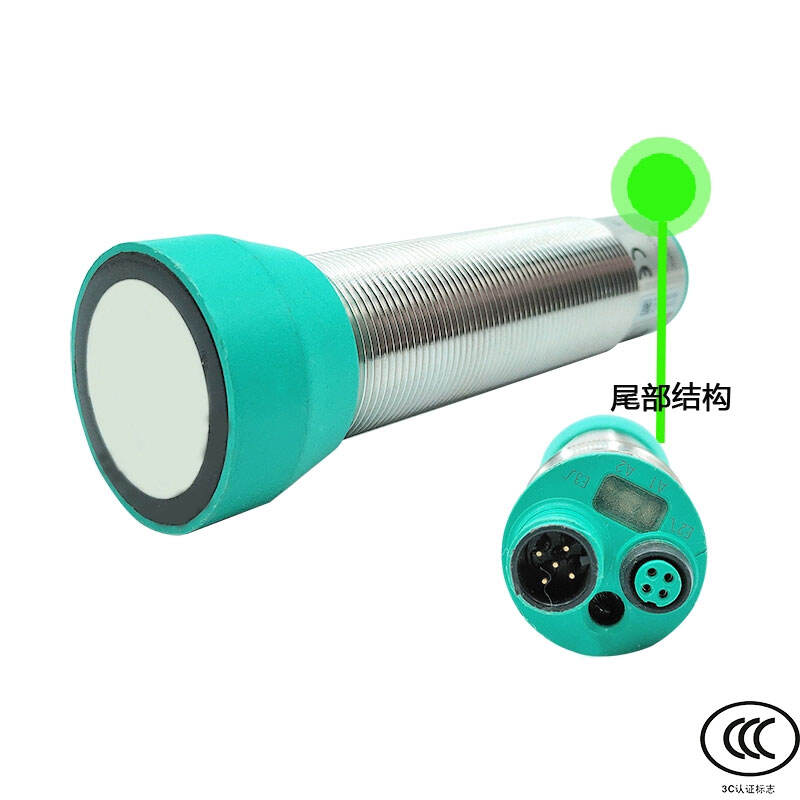

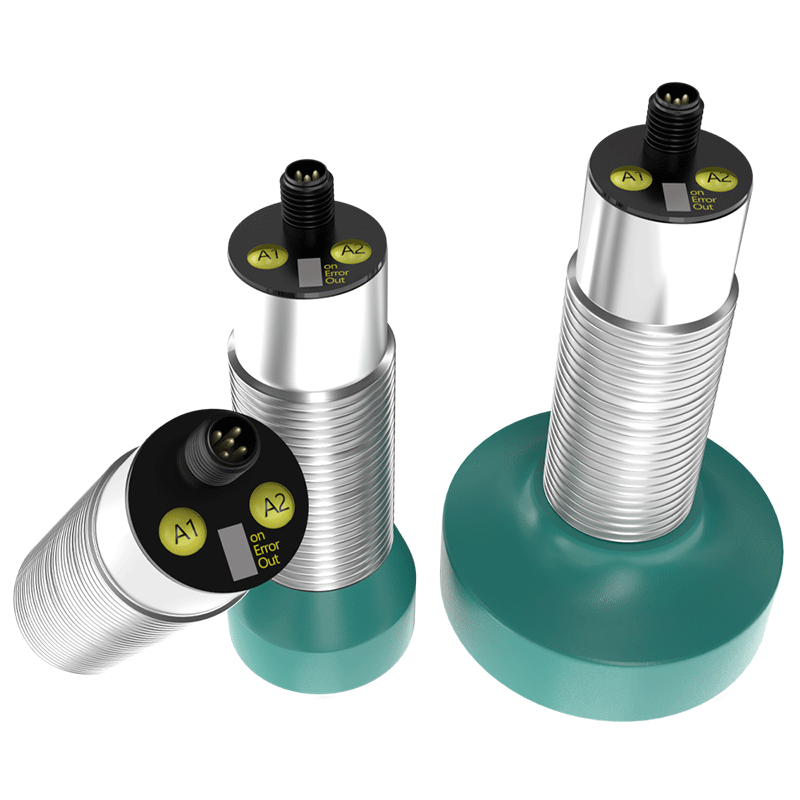

To measure the amount of liquids and solids in a container, the Ultrasonic Sensor Level Proper is a highly accurate device. Capabilities associated with the main functions of this sensor are continuous monitoring, highly precise level data and safety integrated into various industrial procedures. Technical features of this sensor include non-contact measurement, which prevents contamination and wear and also advanced signal processing that filters out any noise for accurate readings. Moreover, the sensor provides a simple user interface and can be ported across a wide range of industrial communication protocols. On the one hand, the level ultrasonic sensor has a whole range of applications in industries like chemical processing and water treatment. On the other, its uncanny precision makes it invaluable in food & beverage manufacturing when level control must not only be exact but also costs-effectively maintained.