Superior Environmental Adaptability

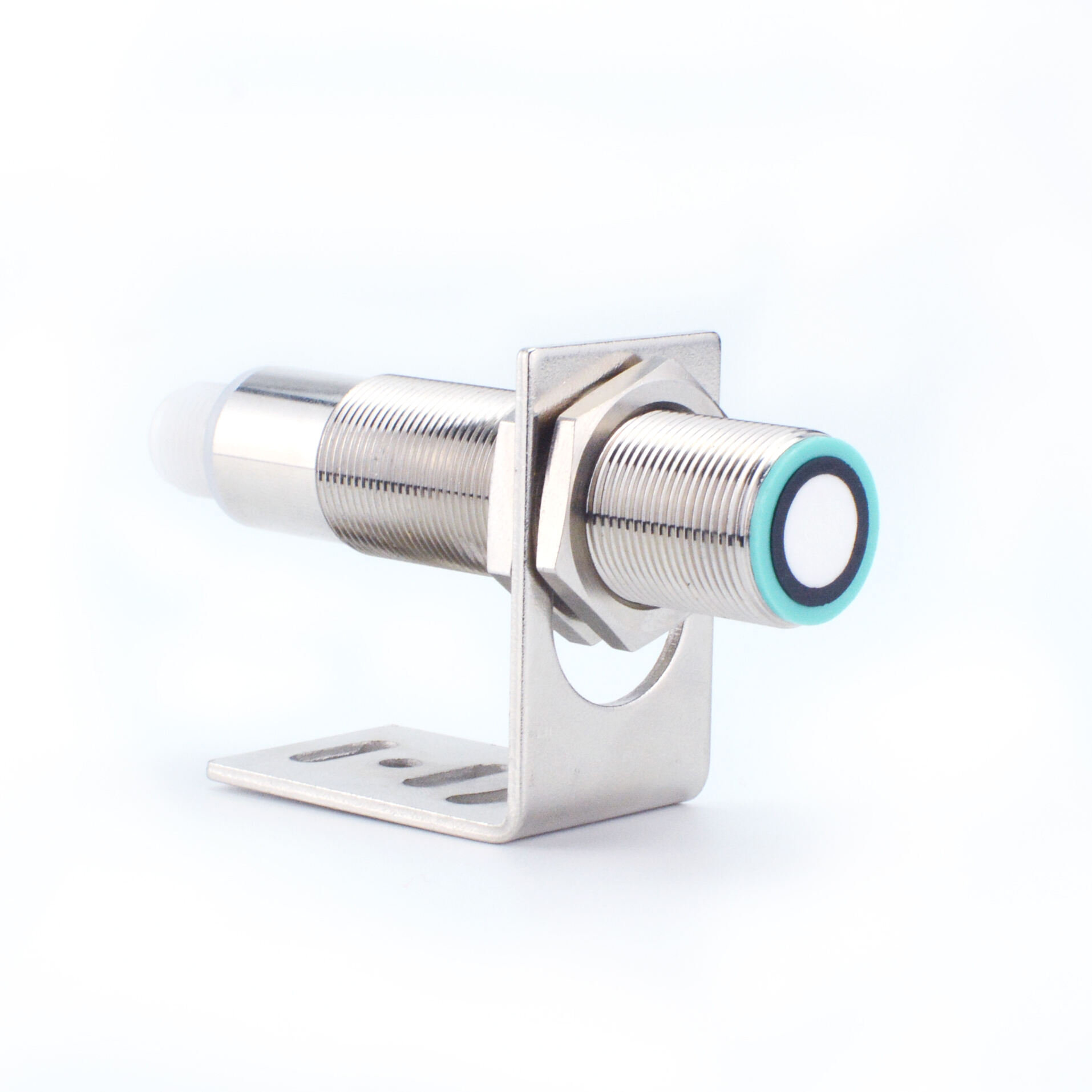

Ultrasonic sensors demonstrate exceptional performance across diverse environmental conditions, setting them apart from alternative sensing technologies. Their unique ability to maintain accuracy in challenging atmospheres, including dusty, humid, or poorly lit environments, makes them invaluable in industrial applications. The sensors employ sophisticated temperature compensation algorithms that automatically adjust measurements based on ambient conditions, ensuring consistent accuracy from -40°C to +70°C. This robust environmental adaptability eliminates the need for additional protective equipment or frequent recalibration, significantly reducing maintenance costs and system downtime. The sensors' sealed construction, typically rated IP67 or higher, provides excellent protection against dust and moisture, enabling reliable operation in wash-down environments and outdoor installations.