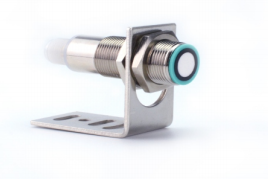

non contact tank level sensor

Non contact tank level sensors represent a cutting-edge solution for measuring liquid levels in various containers without physical contact with the medium. These sophisticated devices utilize advanced technologies such as ultrasonic waves, radar, or laser beams to accurately determine fluid levels. The sensor emits signals that bounce off the liquid surface and return to the detector, calculating the distance based on the time taken for the signal to return. This modern approach ensures precise measurements while eliminating the risk of contamination and mechanical wear associated with traditional contact sensors. The technology operates effectively across diverse industrial applications, from chemical processing to water treatment facilities, offering real-time monitoring capabilities with exceptional accuracy. These sensors can function reliably in challenging environments, maintaining consistent performance despite variations in temperature, pressure, or chemical composition of the measured medium. They support integration with modern control systems through standard communication protocols, enabling automated monitoring and control of liquid levels. The versatility of non contact tank level sensors makes them suitable for various tank sizes and shapes, while their maintenance-free operation significantly reduces operational costs. Their ability to measure through foam, vapor, and turbulent conditions ensures reliable readings in complex industrial processes.