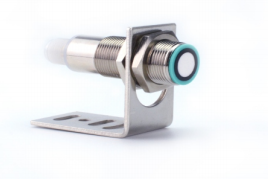

photoelectric sensor

A photoelectric sensor is a sophisticated electronic device that uses light beams to detect the presence, absence, or distance of objects in various industrial and commercial applications. This versatile sensor operates by emitting a light beam, typically infrared, visible red, or laser, and measuring changes in the received light when objects interrupt or reflect the beam. The sensor consists of two main components: an emitter that projects the light beam and a receiver that detects the light signal. These sensors can be configured in three primary modes: through-beam, retro-reflective, and diffuse reflection. Through-beam arrangements utilize separate emitter and receiver units positioned opposite each other, offering the longest sensing range and highest reliability. Retro-reflective sensors use a reflector to bounce the light beam back to a receiver housed in the same unit as the emitter, providing a cost-effective solution for medium-range detection. Diffuse reflection sensors detect objects based on the light reflected directly from the target, making them ideal for close-range applications. Modern photoelectric sensors incorporate advanced features such as background suppression, foreground suppression, and precise digital calibration capabilities, enabling them to function reliably in challenging industrial environments while maintaining high accuracy and repeatability.