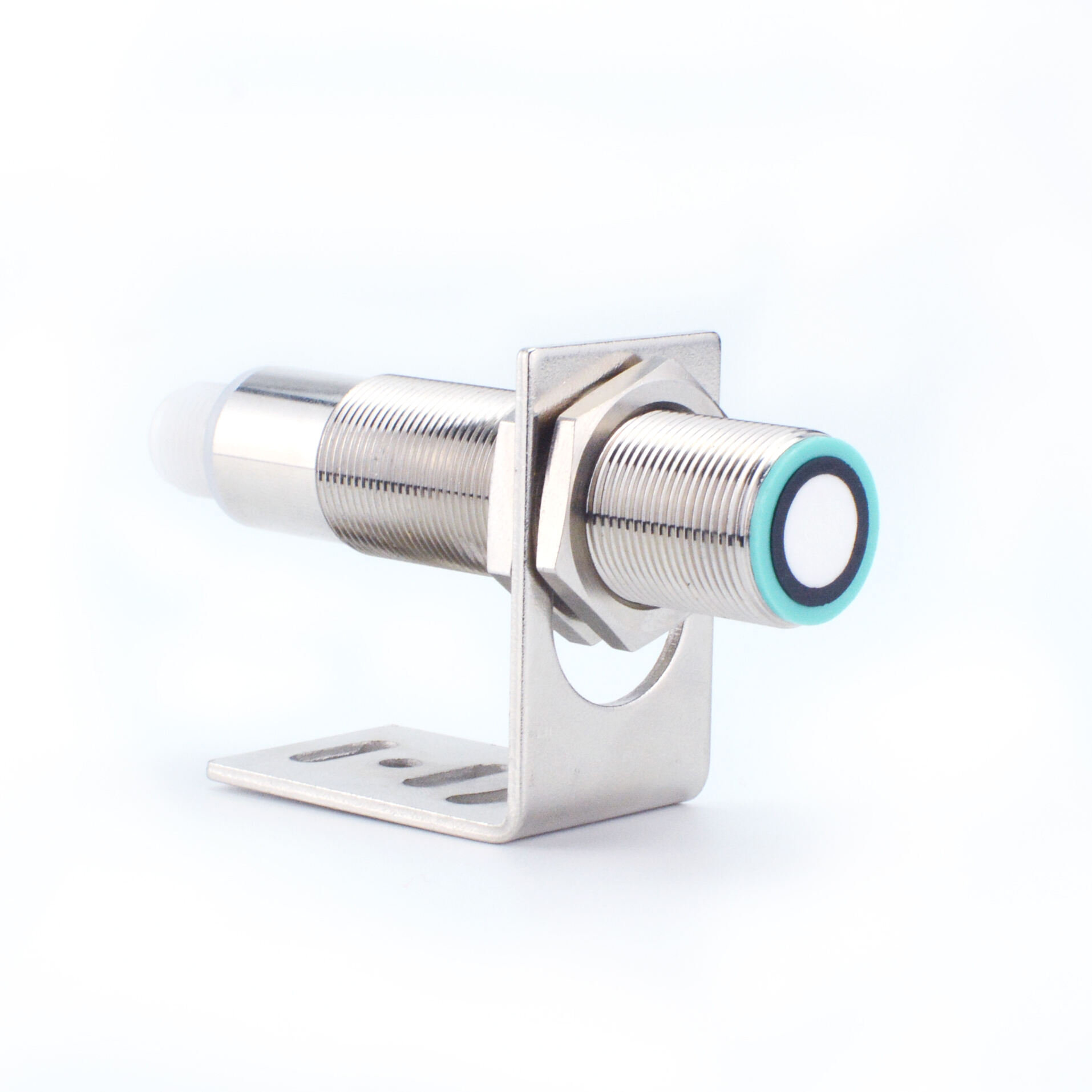

non contact liquid level sensor

Non-contact liquid level sensor is a sophisticated apparatus to measure the level of liquid in some place. This sensor uses state-of-the-art technologies like ultrasonic, radar or optics to ascertain liquid levels. The main functions of This sensor include continuous level monitoring detection of overflow, or a lack of liquid in irrigation systems accurate data for process control systems. Technological features of this sensor include the place in which it can work, anti-corrosion properties and its compatibility with a wide range liquid types - including aggressive chemicals. Its applications range in various industries from water treatment and chemical processing to food and drink production where precision is essential.