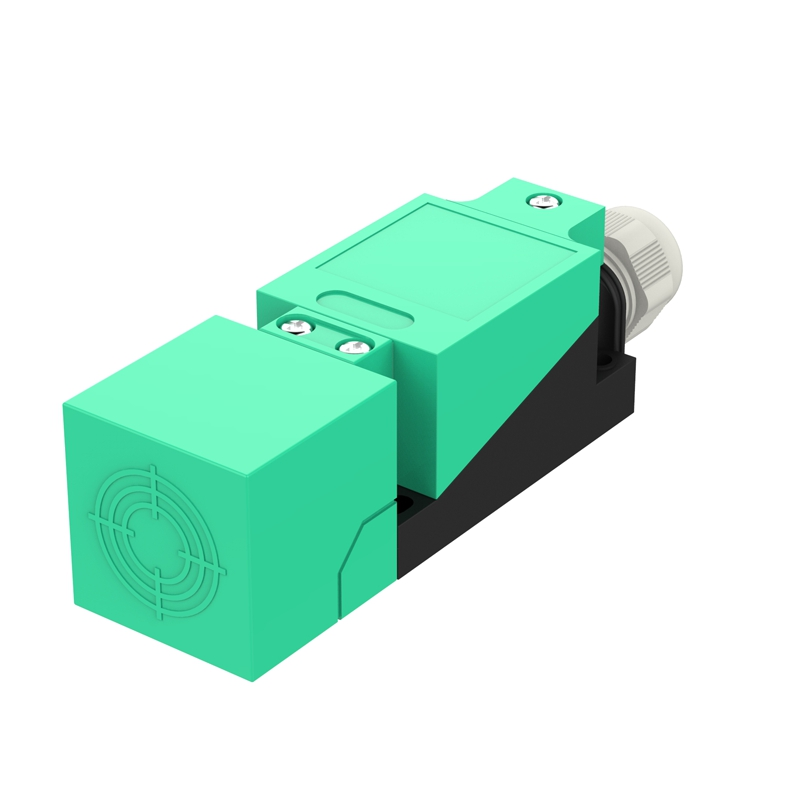

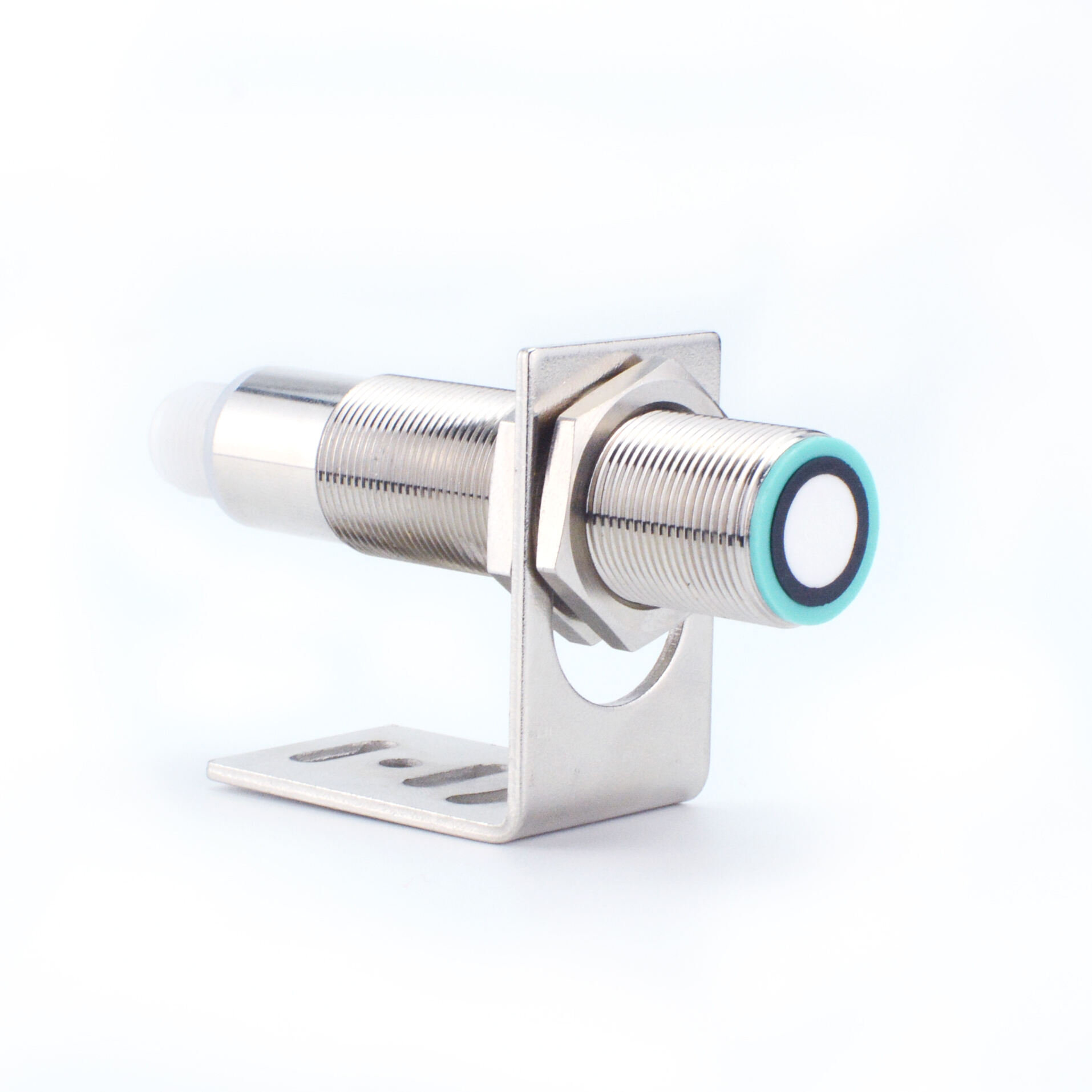

ultrasonic liquid level switch

The ultrasonic liquid level switch represents a cutting-edge solution in fluid level measurement technology, utilizing advanced ultrasonic waves to accurately determine liquid levels in various containers and vessels. This innovative device operates by emitting high-frequency sound waves that travel through the liquid medium and reflect off the surface, enabling precise measurement of fluid levels. The switch incorporates sophisticated signal processing capabilities that can differentiate between the liquid surface and potential interference, ensuring reliable and accurate readings. Its non-contact measurement principle eliminates the need for direct interaction with the measured liquid, making it particularly suitable for hazardous or corrosive substances. The device's versatility allows it to function effectively across a wide range of industrial applications, from chemical processing and water treatment to food and beverage manufacturing. The ultrasonic liquid level switch features robust construction, typically housed in weatherproof enclosures that protect against environmental factors. Its digital display provides real-time level information, while multiple output options facilitate seamless integration with existing control systems. The switch can be configured to trigger alarms or automated responses at predetermined level thresholds, offering both monitoring and control capabilities in a single unit.