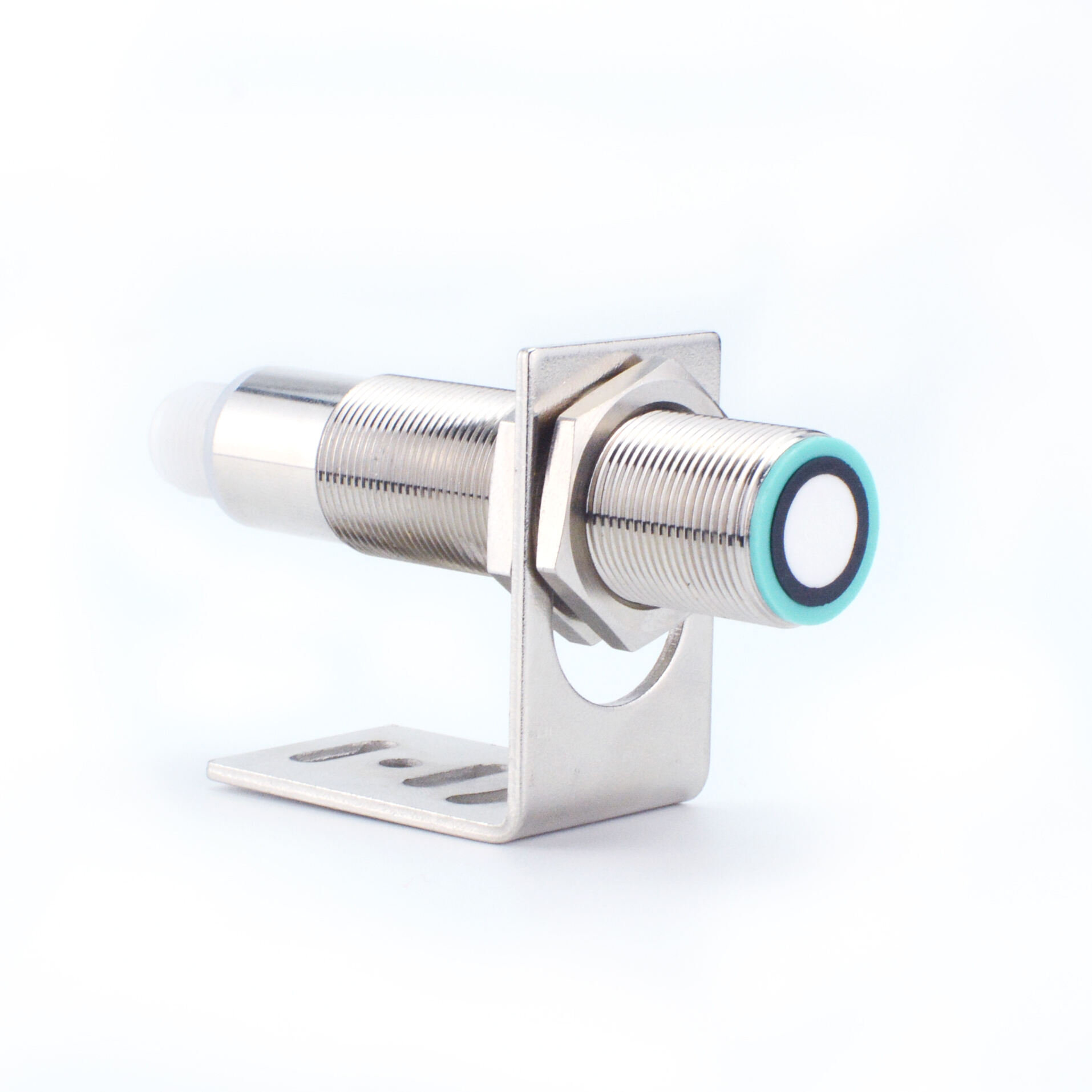

ultrasonic sensor range

With regard to ultrasonic sensors, this scientific name refers to detecting the presence, position and distance using high frequency sound wave methods. It has excellent performance on its main functions, the main obstacle being how to avoid hitting something which is too late for you to notice or turn away from. These special sensors can excellently measure distance without mechanical contact with the object. They rely on an ultrasonic pulse to generate echo information and ECHO return The time it takes Considering such features as compact design, robustness and non-contact measurement capabilities, which are typical of modern ultrasonic sensor technology, these sensors are suitable for a wide range of applications. The sensors work by emitting an ultrasonic pulse and measuring how long it takes for the echo to come back. This time is converted into a distance measurement. They are used extensively in industry such as monitoring and controlling processes, for example, on the production line of an automobile assembly plant. Some kinds of this sensor are also found in automotive turn indicators showing park assistance status. Robotics, automotive support systems for parking assistance have an important application of the other cars: cars which are capable of driving and parking themselves are not yet available but there will be some day Industrial bearings.