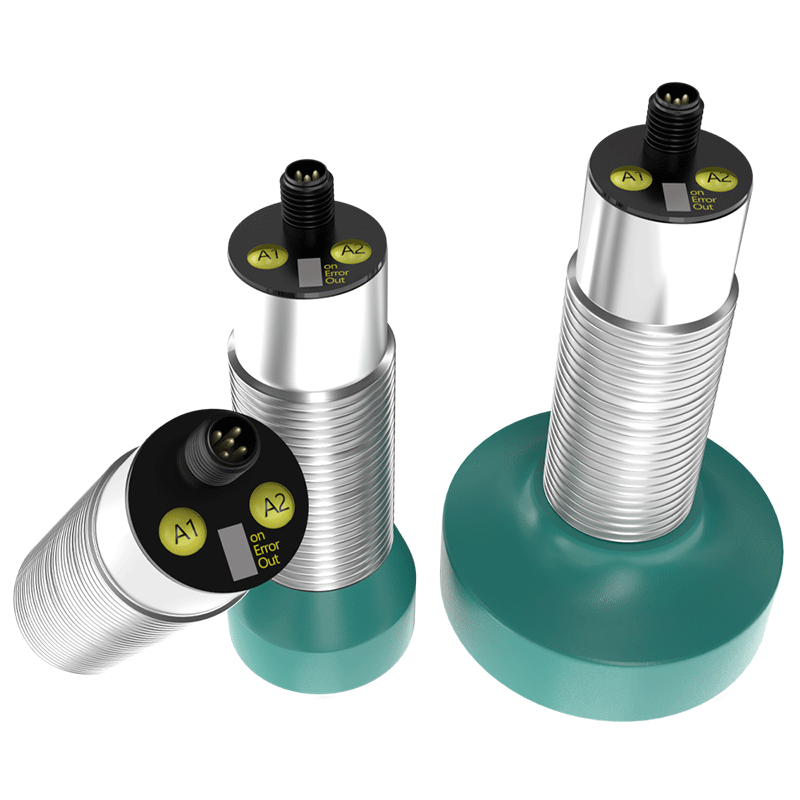

ultrasonic sensor level measurement

The ultrasonic sensor liquid level measurement is an advance technology for measuring liquid and solid levels in general use.Ultra sonic wave is emitted and the time it takes to get back after it encountered the target's surface is measured. This time is then used to compute the distance to target, thereby providing an accurate level reading. Technological features include non-contact measurement, which alleviates the chance of contamination, and an ability to work with materials from a wide range regardless their dielectric constant. The applications of this sensor are quite widespread, with its use in industries ranging from chemicals and pharmaceuticals to food and drink processing where high precision level control may be crucial.