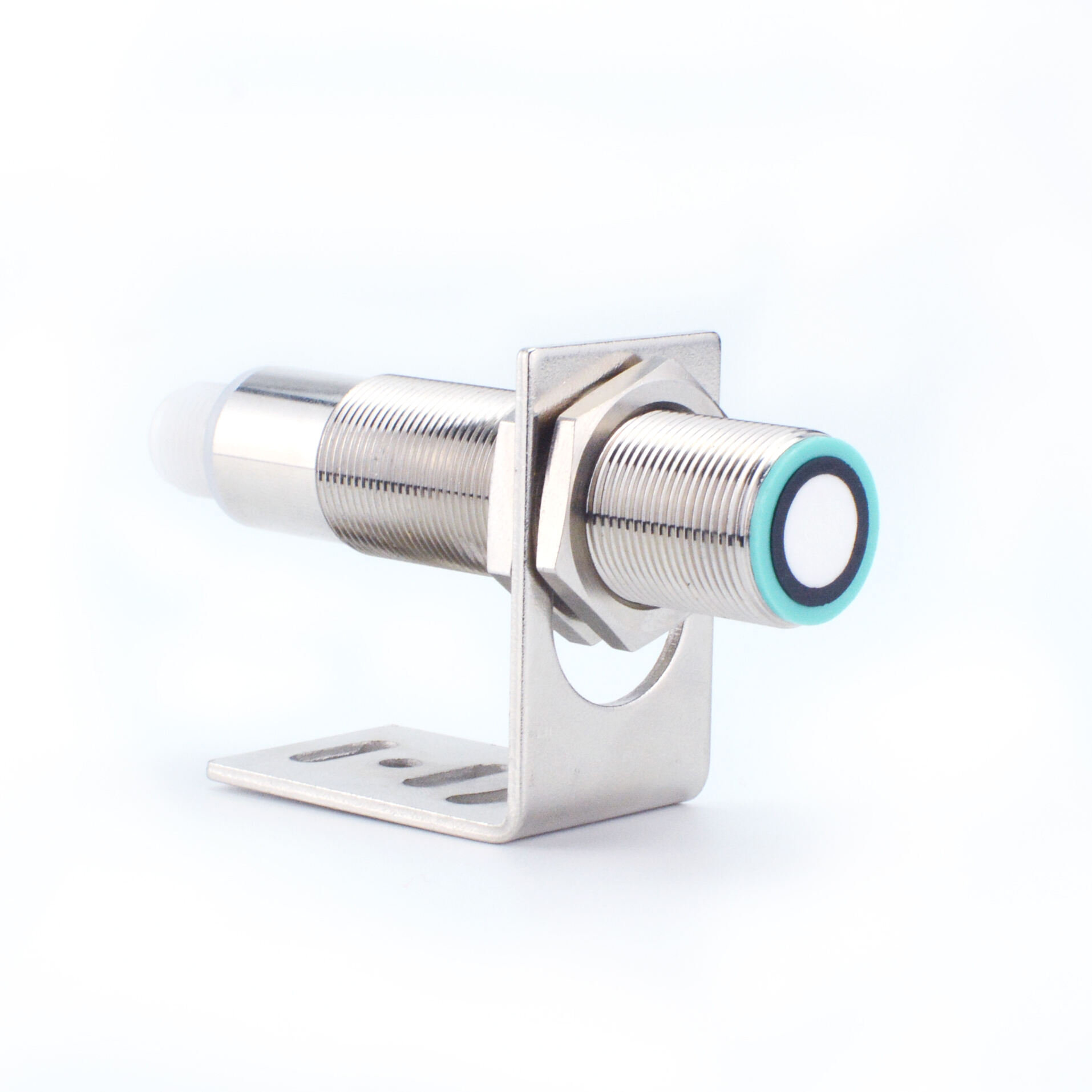

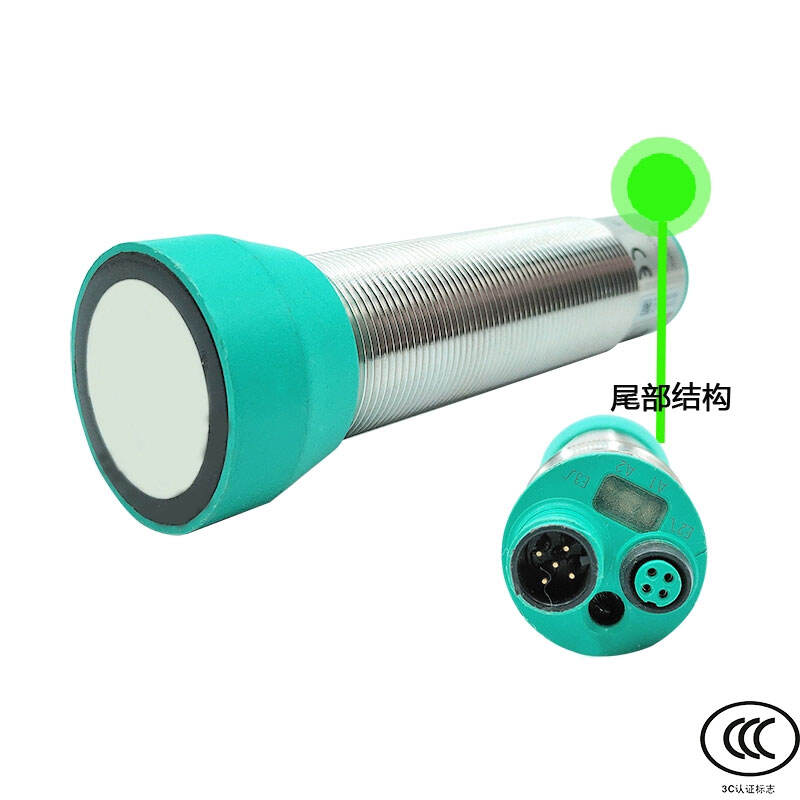

ultrasonic tank sensor

The ultrasonic tank sensor represents a cutting-edge solution for precise liquid level measurement in various storage containers and vessels. This sophisticated device operates by emitting high-frequency sound waves that bounce off the liquid surface and return to the sensor. By measuring the time taken for these waves to travel, the sensor accurately calculates the liquid level within the tank. The technology incorporates advanced signal processing algorithms to filter out interference and ensure reliable readings in diverse environmental conditions. These sensors are designed to work with a wide range of liquids, including water, chemicals, and oils, making them versatile tools for industrial applications. The non-contact measurement principle eliminates the risk of contamination and reduces maintenance requirements, while the robust construction ensures long-term durability in harsh industrial environments. Modern ultrasonic tank sensors often feature digital displays, multiple output options, and integration capabilities with existing control systems. They can be configured to provide continuous monitoring, set point alarms, and data logging functions, enabling efficient inventory management and process control. The sensors typically operate within a temperature range of -40 to 80 degrees Celsius and can measure distances up to 15 meters, depending on the model specifications.