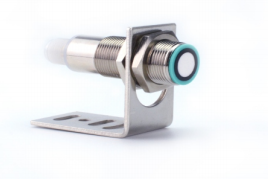

ultrasonic water level controller

It is an innovative device designed to monitor and manage water levels in various applications. It means continuous level sensing, accurately measuring water levels and automatically controlling water flow. Advanced ultrasonic technology is used in this controller to emit high-frequency sound waves that bounce off the water surface. Then, by analyzing the reflected waveforms, it must calculate where the water is and produce analogue signals representing that distance. Technologically, the non-contact design of the controller eliminates any chance of corrosion, and its interface is easy to install. The instrument also supports several industrial protocols. The ultrasonic water level controller has wide uses. Whether sludge depositing in a sewage works or algae growing on the surface of ponds, in many situations where water quality is of great concern this lengthy problem can be tackled within days.