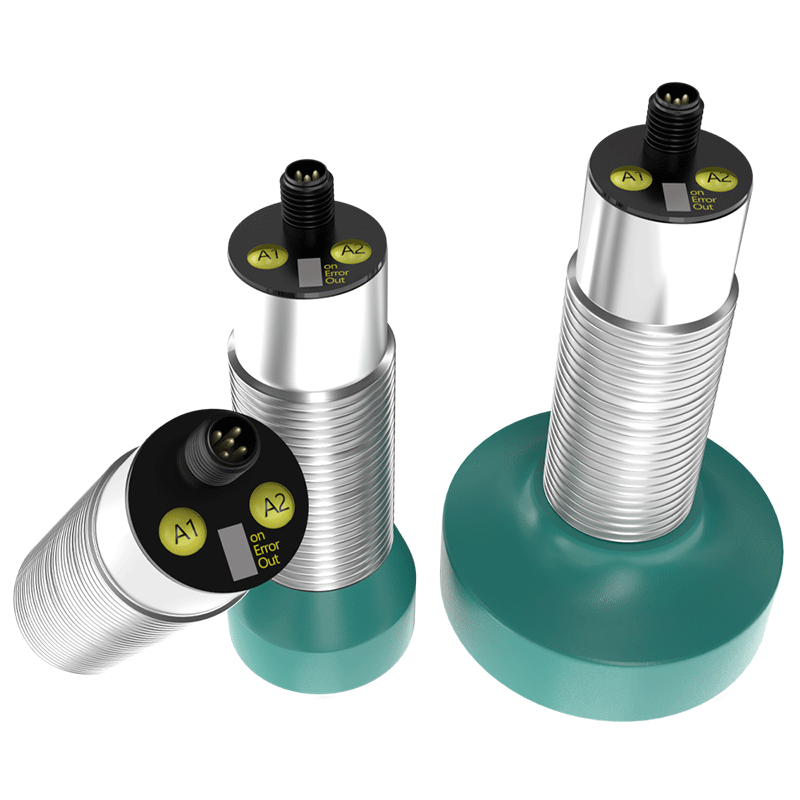

ultrasonic meters

Ultrasonic meters represent a cutting-edge solution in flow measurement technology, utilizing sound waves to accurately measure liquid flow rates in various applications. These sophisticated devices operate by transmitting ultrasonic pulses between transducers, calculating flow rates based on the time difference between upstream and downstream signals. The technology employs advanced digital signal processing to ensure precise measurements across a wide range of flow conditions. These meters are designed with no moving parts, making them highly reliable and maintenance-free. They excel in measuring both clean and slightly contaminated liquids, offering exceptional accuracy typically within ±0.5% of reading. The meters feature robust construction, usually incorporating stainless steel or brass housing, ensuring durability in diverse industrial environments. Advanced models include digital displays, multiple communication protocols, and data logging capabilities, enabling seamless integration with modern control systems. Their application spans various industries, including water utilities, chemical processing, heating, ventilation, and air conditioning (HVAC) systems, and industrial process monitoring. The meters can handle pipe sizes from small residential applications to large industrial installations, with some models capable of managing flow rates up to several thousand gallons per minute.