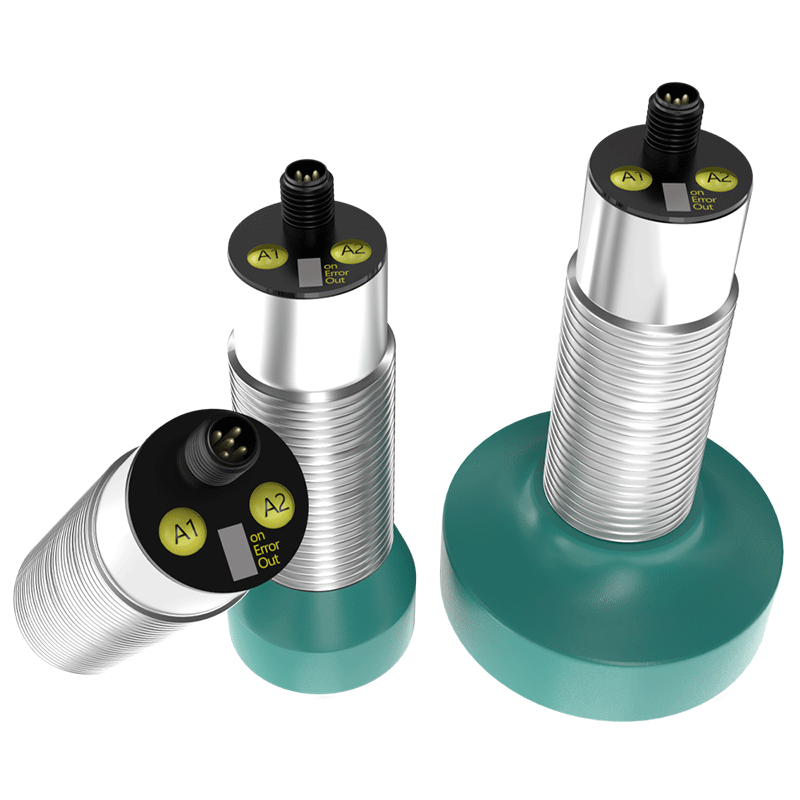

non contact liquid sensor

The non contact liquid sensor is a sophisticated device designed to detect the presence, level, and volume of liquids without any physical interaction. Using advanced ultrasonic, optical or capacitive technology, this sensor is able to precisely measure and monitor liquid conditions. Its main functions include continuous level monitoring, tracking drops (non-touch measurement), point level detection and flow metering for liquids. In industries such as chemicals, food and beverage production as well as pharmaceuticals and treatment of clean water, this sensor has become the standard tool. With features like programmable setpoints for conductivity, real time reporting of the parameters in liquid measurement as well as compatibility with a wide range of fluids this device is widely used worldwide. The non contact design greatly reduces the danger of contamination, wearing out or breaking down, and makes for a reliable and low-maintenance sensing tool in liquid environments.