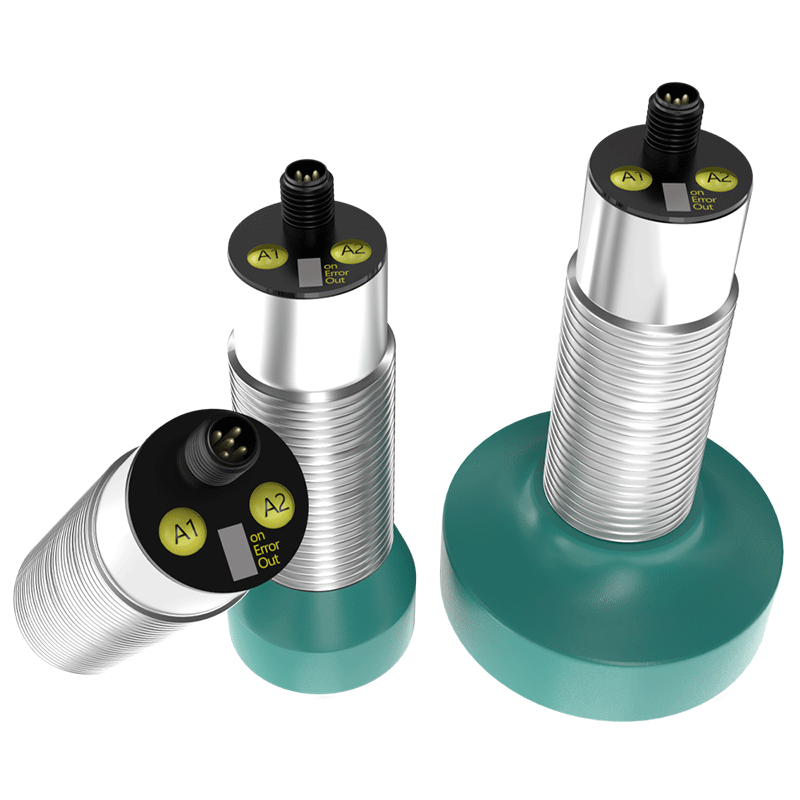

ultrasonic fluid level sensor

Designed to calculate the level of liquids and vapors within an array of facilities, the ultrasonic fluid level sensor is an extensive instrument. the main functions of this instrument include continuous level monitoring, high-precision volume measurements and reliable safety monitoring as well as intelligent design features in various industries The chief technical features of this sensor are its capability for non-contact measurement, resistance against corrosive materials in addition to a high degree of fluid compatibility. It sends out energy in ultrasonic waves which rebound from the surface of the liquid and are detected by sensors. The level is calculated from this distance, together with time that has elapsed. Ultrasonic fluid level sensors have manifold applications such as water treatment and chemical processing, and they are also increasingly applied to fuel management within industrial settings.