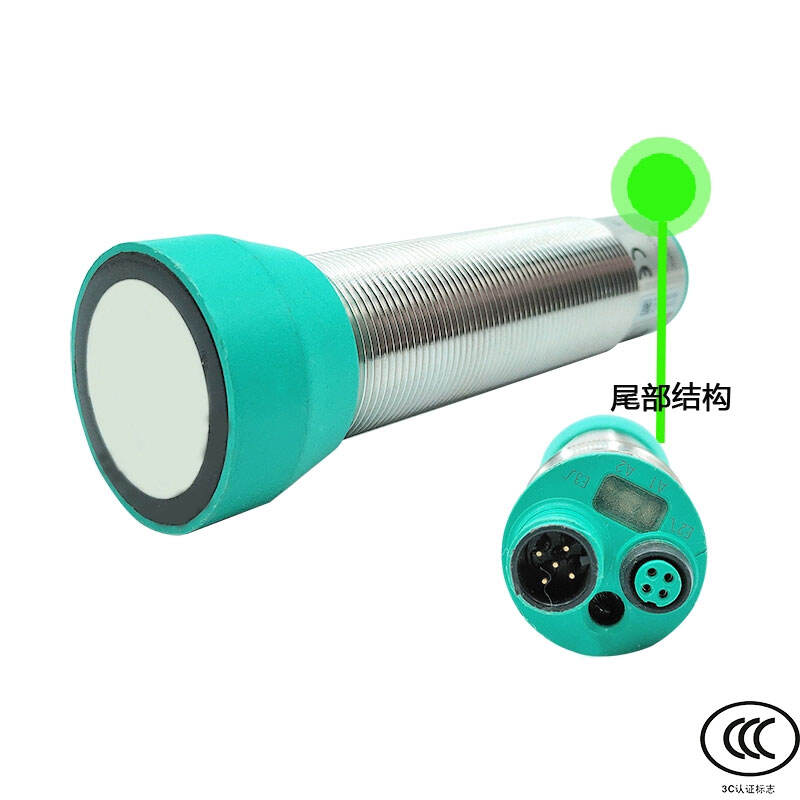

ultrasonic type level measurement

Ultrasonic level measurement is a leading-edge technology used to determine liquid or solid levels inside tanks. It has two major functions: accurate and continuous level monitoring, which is key to process control and management of stock in hand. This technology features a non-contact design: high frequency sound waves travel from transmitter to the material being measured and then return back. The time taken for the echo to come back is converted into a level reading. Other characteristics include advanced signal processing, materials that are resistant to corrosion, and compatibility with a wide range of materials and process conditions. Applications begin in forest of bayberry, extend to chemical & petrochemical, from medicine food--to meet higher demands on certainty of level. Precise level control for safety, efficiency and quality product starts with accurate level measurement.