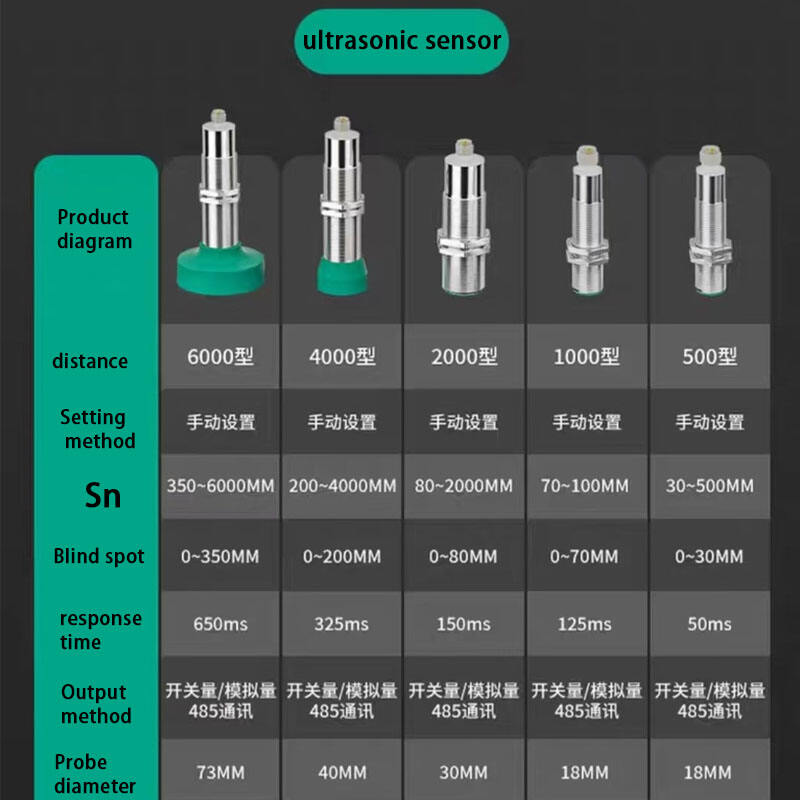

ultrasonic level measurement

Ultrasonic level measurement represents a sophisticated non-contact technology that utilizes sound waves to determine the level of various substances in tanks, vessels, and containers. Operating on the principle of time-of-flight measurement, this technology emits high-frequency sound waves that bounce off the material surface and return to the sensor. The device calculates the distance by measuring the time taken for the sound wave to travel to and from the target surface. This innovative measurement solution offers exceptional versatility across numerous industries, including water treatment, chemical processing, food and beverage production, and pharmaceutical manufacturing. The technology excels in measuring both liquid and solid materials, providing accurate readings regardless of material properties such as color, transparency, or electrical conductivity. Modern ultrasonic level measurement systems incorporate advanced signal processing capabilities that effectively filter out false echoes and compensate for changing environmental conditions. These systems typically feature user-friendly interfaces, digital displays, and various output options for seamless integration with existing control systems. The technology's non-invasive nature ensures measurement without direct contact with the medium, making it particularly valuable for handling aggressive, corrosive, or hygiene-sensitive materials. Additionally, these systems often include diagnostic capabilities that help maintain measurement reliability and facilitate preventive maintenance schedules.